CK45 42CrMo4 Chromed adag

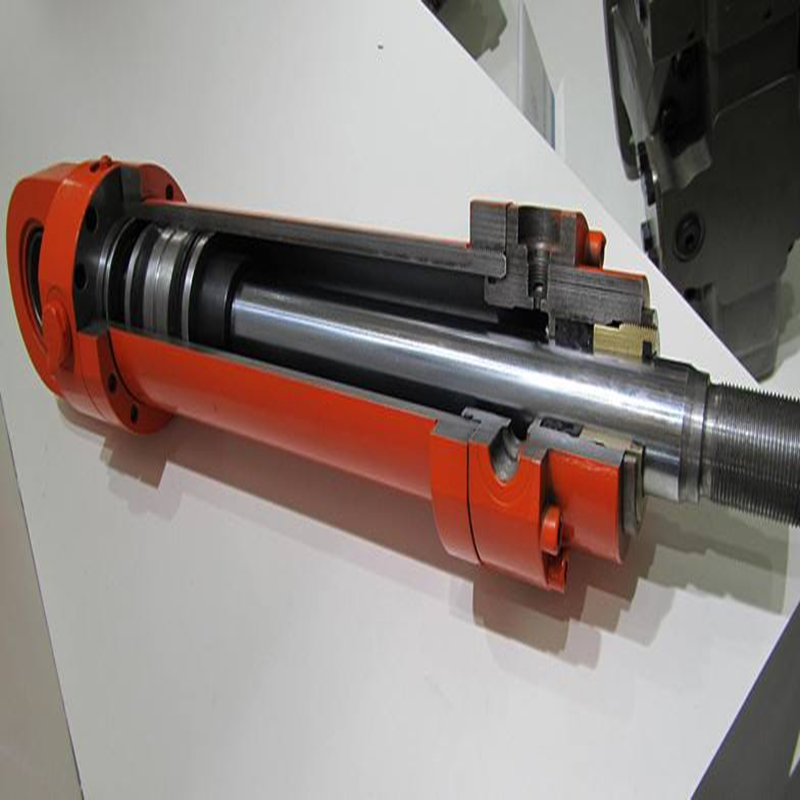

Faahfaahinta Sawirada

Tilmaamaha Farsamada

| Dhexroorka | 6-300mm |

| Dhererka | 100mm-1200mm |

| Heerka birta | DIN CK45JIS 45C ASTM 1045 SAE 1045 AISI 1045 |

| Dulqaad | ISO f7 |

| Dhumucda Chrome | 20μm (daqiiqo) |

| Adag ee lakabka chrome | 850HV (daqiiqo) |

| Qalafsanaan | Ra 0.2μm (ugu badnaan) |

| Toosanaan | 0.2/1000mm |

| Guryaha Makaanikada (ck45) | Awood soo saarid≥20MpaXoog xajin≥80 MpaKordhinta≥5% |

| Xaaladda sahayda | 1.Chrome dahaadh adag |

| 2.Induction qallafsantay | |

| 3.Demiyay & xanaaqay | |

| 4.Induction ku adagtahay Q&T |

Halabuurka Kiimikada

| Qalab | C% | Mn% | Si% | S% | P% | V% | Cr% |

| Ck45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| ≤0.25 |

| ST52 | ≤0.22 | ≤1.6 | ≤0.55 | ≤0.04 | ≤0.04 | 0.02-0.15 |

|

| 20MnV6 | 0.17-0.24 | 1.30-1.70 | 0.10-0.50 | ≤0.035 | ≤0.035 | 0.10-0.20 | ≤0.30 |

| 42CrMo4 | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | 0.07-0.12 | 0.90-1.20 |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 |

| 0.80-1.10 |

Guryaha Makaanikada

| Qalab | TS N/MM2 | YS N/MM2 | E%(MIN) | CARABY | XAALADDA |

| CK45 | 610 | 355 | 15 | >41J | CAADI |

| CK45 | 800 | 630 | 20 | >41J | Q + T |

| ST52 | 500 | 355 | 22 |

| CAADI |

| 20MnV6 | 750 | 590 | 12 | >40J | CAADI |

| 42CrMo4 | 980 | 850 | 14 | >47J | Q + T |

| 40Cr | 1000 | 800 | 10 |

| Q + T |

Baakadaha

Saliid-ka-hortagga ul kasta

Saliid-ka-hortagga ul kasta

Gacanka warqadda ul kasta

Ama Sida waafaqsan Shuruudaha Macmiilka.

Waxaan Higsaneynaa Ku Qanacsanaantaada !

Codsiga

Inta badan loo isticmaalo dhululubada haydarooliga, dhululubada pneumatic, tiirarka hagaha

qalabka soo socda:

Mashiinada Dhismaha, Mashiinada, Mashiinada Macdanta, Mashiinada Dharka, Mashiinada Daabacaada.